The Aluminum Truck Tool Box Advantage

If you own a truck, you know that storage space can sometimes feel...lacking. Whether you're hauling tools for work, camping gear for the weekend, or emergency supplies just in case, you need a solution that’s tough, reliable, and built to last. That’s where UWS aluminum tool boxes come into play.

Why Choose an Aluminum Truck Tool Box?

Tool boxes are available in a few different materials: steel, plastic, and aluminum being the most common. So, why is aluminum the top pick for so many truck owners? It comes down to a winning combination of strength, weight, durability, and maintenance-free performance.

1.) Lightweight Yet Strong

Aluminum offers an exceptional strength-to-weight ratio. It’s tough enough to withstand the daily demands of work and travel, but light enough that it won’t weigh down your truck or hurt your gas mileage.

2.) Naturally Rust-Resistant

Unlike steel, aluminum doesn’t rust. Period. That makes it ideal for use in rain, snow, salty coastal air, or muddy jobsite conditions. While steel tool boxes often require painting or special coatings to prevent corrosion, aluminum boxes remain resilient with minimal upkeep. Just an occasional rinse to clear dirt or debris, and you’re good to go.

3.) Low Maintenance

One of the biggest advantages of aluminum is just how little attention it demands over time. Unlike steel, which may require frequent painting, rust treatment, or corrosion prevention measures, aluminum is naturally resist to the elements. You won’t have to worry about chips in the paint leading to rust, and you won’t need to apply primers or sealants to keep your box in good shape. Aluminum won’t warp or crack from temperature swings, and it stands up to UV exposure without fading or weakening. Even under tough working conditions, like freezing winters and scorching hot summers, aluminum will still hold its shape.

4.) Top Weather Protection

There isn’t much use for a tool box if water gets inside and aluminum does an excellent job of forming a tight, reliable barrier when paired with smart design features. UWS aluminum truck tool boxes use high-quality weather stripping along the lid to keep moisture, dust, and debris out. So whether you’re driving through a downpour or parked in a dusty field, your tools and gear remain dry, clean, and protected. Combine that with reinforced lids, strong latches, and secure locking systems, and you get peace of mind in any weather which is especially important if you’re storing power tools, electronics, or sensitive gear.

5.) Sleek, Professional Style

There’s no denying it: aluminum truck tool boxes look good. The sharp lines of a diamond-plate complement your truck’s aesthetic while adding a professional, rugged look. Whether you drive a work truck or a weekend adventure rig, aluminum boxes add utility without compromising appearance.

6.) Eco-Friendly & Sustainable

Aluminum isn’t just tough and good-looking. It’s also one of the most environmentally responsible material choices you can make. Unlike plastic or coated steel, aluminum is 100% recyclable without losing quality, meaning it can be reused repeatedly with minimal environmental impact. So when you invest in an aluminum truck tool box, you’re not only choosing durability. You're also choosing a material that supports sustainability.

What Makes UWS Aluminum Tool Boxes Better Than The Rest?

At UWS, we don’t just build tool boxes. We build better tool boxes. Here's what makes our aluminum truck tool boxes the trusted choice of tradespeople, contractors, weekend warriors, and everyday truck owners nationwide.

RigidCore™ Lid Technology

Our advanced RigidCore™ lid is one of our proudest innovations. We inject a solid foam core into every lid to maximize rigidity and prevent the warping, flexing, or sagging that can develop over time with hollow lids. You’ll notice the difference every time you open it.

Extra-Thick Aluminum Construction

Most UWS boxes are crafted from 0.058” thick aluminum, while many competitors use thinner 0.045” sheets. That extra material adds significant structural integrity, helping your tool box resist dents, dings, and warping even under heavy loads. Whether it’s bouncing along a back road or braving a full workday, a UWS box stays solid.

MicroSeal™ Gasket

Say goodbye to dust and water getting into your tool box. Our MicroSeal™ gasket is designed to create a tight, dependable seal around the lid, keeping your tools safe, dry, and clean no matter where the job takes you.

Assembled in the USA

Every UWS aluminum truck tool box is proudly engineered, cut, welded, assembled, and finished in the USA. That means tighter quality control, faster support, and a commitment to American craftsmanship. Plus, UWS backs its tool boxes with a limited lifetime warranty. If something’s not right, we’ll make it right. It’s that simple.

See the UWS Difference

Types of Aluminum Truck Tool Boxes

No two truck owners use their vehicles the same way, and the right truck tool box for you depends on your daily needs, your cargo, and how you use your bed space. Whether you're a contractor, a weekend DIYer, or someone who just wants to keep their tools dry and organized, there’s a UWS aluminum tool box designed to match your setup.

Crossover Tool Boxes

Also known as saddle boxes, crossover tool boxes are a classic for a reason. They mount directly behind the cab and “cross over” the truck bed, resting on the bed rails without touching the floor. This creates a floating design that preserves valuable bed space underneath. Crossover truck tool boxes are perfect for hauling lumber, ladders, or equipment that need the full floor of the bed.

Best For:

- General-purpose use

- Jobsite tool

- Maximizing usable bed floor space

- Easy access from outside the truck bed

Utility Chests

Unlike crossover boxes, utility chests are installed on the truck bed floor, usually flush against the cab. Because they don’t span the bed rails, utility chests are fully compatible with most tonneau covers — a major plus for truck owners who want a tool box and covered bed at the same time.

UWS utility chests are available in different lengths and heights, allowing you to choose between maximum capacity or a lower-profile design that stays out of the way. Many models also include dual gas struts and integrated lock systems for smooth, secure access.

Best For:

- Larger or bulky gear

- Covered-bed setups

- Truck owners who want maximum space and flexibility inside the rails

Side-Mount Tool Boxes

When frequent, quick access to tools is your top priority, side-mount tool boxes are the way to go. These boxes install along the inside edges of the bed rails, sitting just above the wheel wells and allowing access through a side-opening lid. This setup is especially popular among contractors, service techs, and utility vehicles, where climbing in and out of the truck bed multiple times a day isn’t practical.

Side-mount boxes can be used alone or combined with other storage options (like a utility chest or crossover box) for a modular storage system that fits your workflow. UWS offers both full-length and compact side-mount boxes to fit a variety of bed sizes and equipment needs.

Best For:

- Tradespeople

- Mobile services

- Fast, easy access to tour tools from the side

- Truck owners looking to build a multi-box system

Other Styles to Consider

While crossover, chest, and side-mount boxes cover most use cases, UWS also offers several specialty aluminum tool box options worth mentioning.

Additional Styles:

- Topside Boxes: Mount above the bed rails or flatbed sides, offering vertical storage and protection. Great for fleet or service trucks.

- Underbody Boxes: Designed for trailers or flatbeds, these mount below the deck and provide hidden storage in otherwise unused space.

- Transfer Tanks with Tool Boxes: Combo units that combine liquid storage (like diesel or chemicals) with built-in tool storage — ideal for ranchers, welders, and equipment haulers.

No matter which type of aluminum truck tool box you choose, UWS builds each one with heavy-duty construction, weather-resistant features, and a focus on smart usability. The right truck tool box doesn’t just hold tools. It transforms how you use your truck.

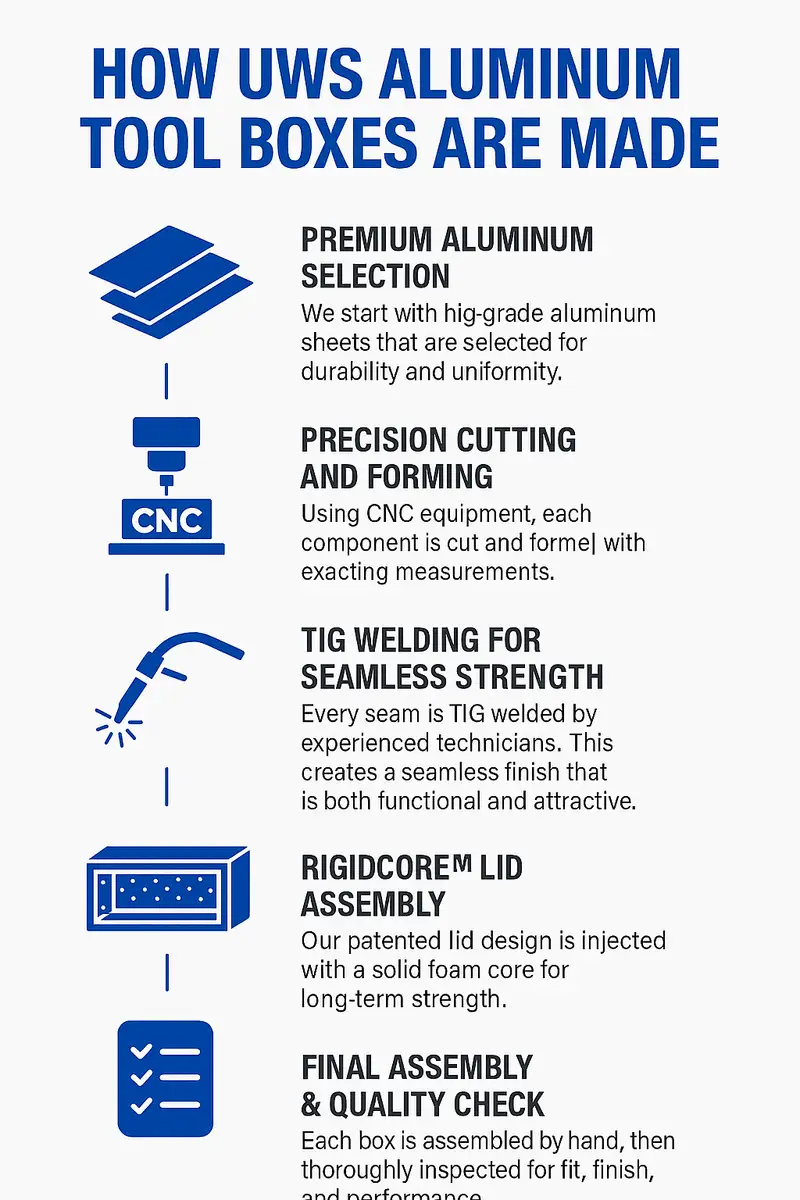

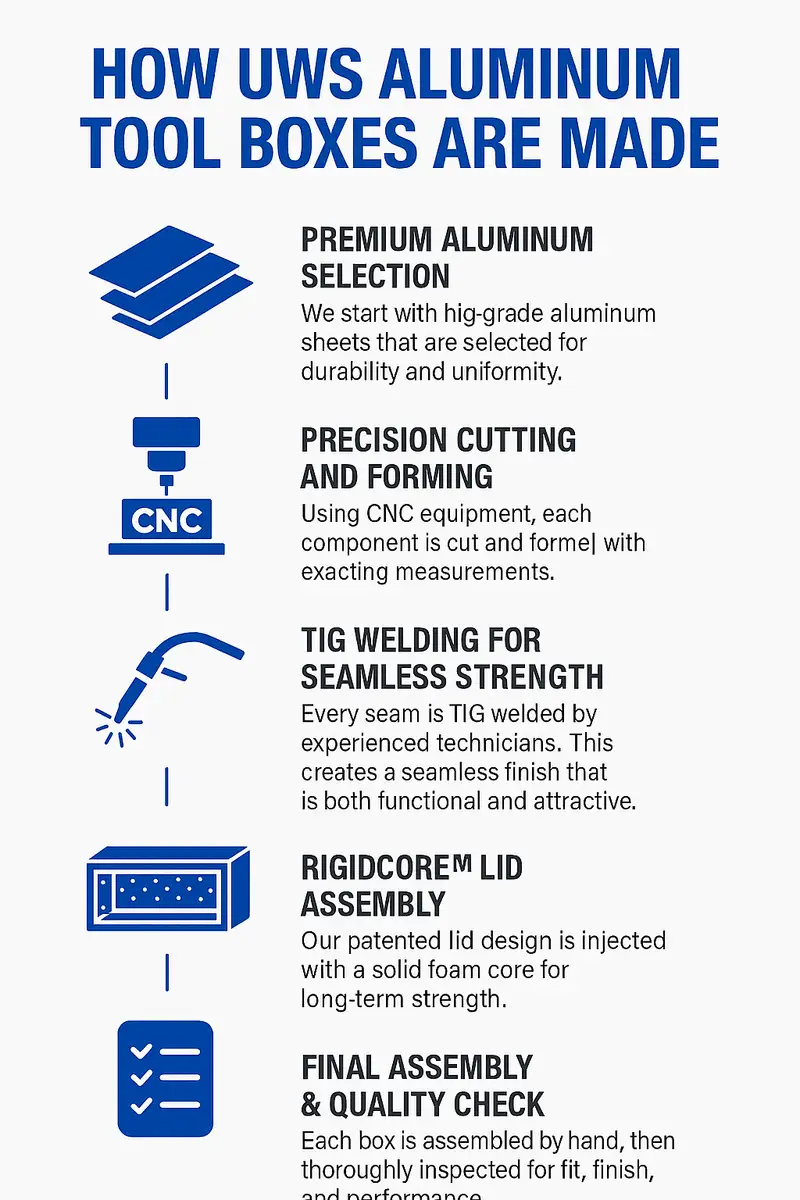

How UWS Aluminum Tool Boxes Are Made

When you open a UWS tool box, you can feel the difference…and that’s not an accident. Our RigidCore lid opens and closes with ease, the welds are smooth and solid, and the entire structure just feels sturdy. That kind of quality isn’t a coincidence. It’s the result of an intentional, step-by-step process rooted in American manufacturing excellence.

1.) Premium Aluminum Selection

It all starts with high-quality, heavy-gauge aluminum. Most UWS boxes use extra-thick 0.058” aluminum, compared to the thinner 0.045” metal you’ll find in many standard boxes. Why does that matter? Because thicker material means more durability, better dent resistance, and a longer lifespan. Each aluminum sheet is selected for consistency, strength, and resistance to corrosion, ensuring a clean and uniform surface. This foundation is critical — a strong box begins with the right material.

2.) Precision Cutting & Forming

Once the aluminum sheets are selected, they’re moved to CNC-controlled equipment where each panel is cut with laser accuracy. Whether it’s a crossover lid, a chest sidewall, or an interior partition, every piece is formed to precise specifications to ensure a perfect fit during assembly. This isn’t a one-size-fits-all operation — every cut and bend is part of a larger plan to deliver maximum strength, ergonomic access, and a streamlined finish that holds up to real work.

3.) TIG Welding for Seamless Strength

After forming, the components are welded together by experienced craftsmen using TIG welding, which is widely known as one of the cleanest and strongest weld types in metal fabrication. TIG (Tungsten Inert Gas) welding produces smooth, uniform welds with minimal spatter, which translates into superior structural integrity and a sleek, professional look. Unlike spot welds or riveted joints, TIG welds provide full-length, continuous bonding. That makes each seam more resistant to stress and vibration over time, which is a crucial advantage when your truck is bouncing around a jobsite or hauling tools down a rough road.

4.) RigidCore Lid Assembly

One of the standout features of our UWS tool box is the RigidCore™ lid. During this step, the lid is injected with a solid foam core, which reinforces the structure and prevents flexing or warping, even under heavy use or extreme temperatures. This foam-filled lid adds more than just durability. It also helps with noise reduction and smoother operation. When you open or close the lid, you’ll notice it feels solid and balanced, not hollow or flimsy like some lesser-built boxes.

5.) Final Assembly & Quality Check

Once the major structural components are in place, it’s time for assembly. Lids are attached using stainless steel hinges, gas struts are installed for smooth lid operation, and interior trays or dividers are added where applicable. Each latch, handle, and seal is individually fitted to ensure flawless function. Our MicroSeal™ gasket is installed during this stage as well, helping to keep out water, dust, and other debris.

Diamond-Plate Aluminum vs. Other Types

The finish on your aluminum truck tool box isn’t just about looks. It plays a big role in how your box performs, holds up over time, and complements your truck’s style. Whether you're hauling tools daily or just need weekend storage, the type of aluminum finish you choose can affect everything from dent resistance to ease of cleaning.

Diamond Plate

This is the go-to finish for UWS tool boxes — and for good reason. Diamond plate features a rugged, raised tread pattern that’s instantly recognizable and highly functional. It’s more than just a tough-looking design.

- Superior Durability: The texture naturally resists warping and denting, making it ideal for rough-and-tumble use on job sites or trails.

- Scratch Camouflage: Scratches and wear marks are less visible thanks to the patterned surface, helping your box look newer longer.

- Long-Term Value: It’s a classic style that holds its resale value, and its proven durability pays off in the long run.

Smooth Plate

Smooth plate aluminum is all about clean lines and modern styling. It has a polished, flat finish that looks sharp, especially on high-end trucks or show builds.

- Sleek Appearance: Smooth plate has a minimalist, refined aesthetic that pairs well with tonneau covers or color-matched setups.

- Easier to Clean: Without texture, it’s quick to wipe down and maintain, but it may also show water spots, fingerprints, or surface damage more easily.

- Best for Controlled Use: If your truck mostly sees paved roads, garages, or light-duty use, smooth plate is a great choice.

Checker Plate & Other Options

Checker plate offers a different texture than diamond plate. It’s finer and squarer than traditional diamond plate. While it’s less common, it provides a unique style that some people prefer for its modern look. Some other options include:

- Powder-Coated Finishes: Available in black, white, or custom colors, powder coating enhances rust resistance and adds a sleek matte or gloss look. It’s popular for matching other truck accessories or branding.

- Brushed or Matte Aluminum: These finishes offer a softer appearance and help reduce glare. They’re ideal for environments where aesthetics matter just as much as function.

- Shiny Aluminum: These finshes offer a shiny apperance that looks good from all angles.

Whether you use your truck for work, play, or a bit of both, an aluminum truck tool box is one of the smartest upgrades you can make. Crafted with pride in the USA, backed by a lifetime warranty, and engineered for the long haul, UWS tool boxes are truly a must-have for storing tools and other equipment. Check out our full lineup of tool boxes and find your perfect fit today.

Aluminum Truck Tool Boxes FAQ

1.) Are aluminum truck tool boxes secure?

Yes. UWS boxes feature secure locking mechanisms, reinforced lids, and tamper-resistant latches to deter theft and keep your tools protected.

2.) Do aluminum truck tool boxes from UWS hold up in tough environments?

Definitely. With thick-gauge aluminum, TIG welds, and RigidCore™ lids, our aluminum tool boxes are built to endure mud, snow, rain, and even light impacts from cargo or gear.

3.) Will an aluminum tool box fit my specific truck?

Most UWS aluminum tool boxes are designed to fit standard truck bed sizes and come in multiple styles (crossover, chest, side-mount, etc.) to match different needs and configurations. Just measure your bed and check compatibility details — or use UWS’ fitment guide to find your ideal match.

4.) Can I install a truck tool box myself? Or do I need a professional?

UWS aluminum tool boxes are designed for easy DIY installation using common tools. Crossover and chest boxes usually clamp to your bed rails or bolt into existing anchor points — no drilling required in many cases. If you’re comfortable with basic tools and measurements, you can absolutely do it yourself in under an hour.

5.) How weather-resistant are UWS aluminum tool boxes?

Extremely. Each tool box is equipped with our MicroSeal™ gasket, a weather-resistant seal that runs around the lid to block water, dust, and debris from getting in. Combined with secure latches and thick aluminum construction, these boxes are ready for all seasons and conditions.

ARIES

ARIES  CURT

CURT  LUVERNE

LUVERNE  UWS

UWS